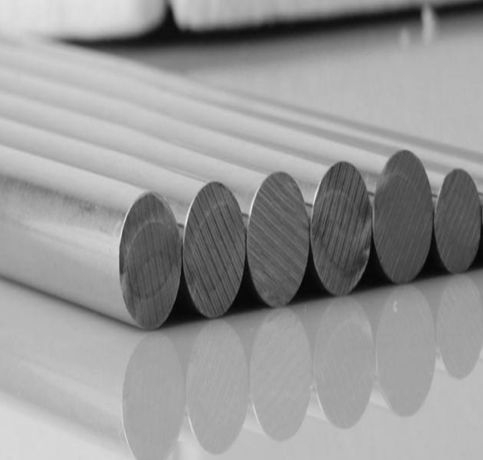

Anucha Metals is a prominent manufacturer, supplier, and exporter of **High Speed Steel T42 bars** in Bangkok, Thailand. With great emphasis on precision, quality, and durability, the company offers T42-grade HSS bars meeting very high industry standards. Renowned for high cutting performance and long tool life, the bars are extensively utilized by manufacturers and toolmakers in the automotive, aerospace, and heavy engineering industries. Anucha Metals provides constant supply, competitive pricing, and dependable technical service, making them an ideal partner for clients in Thailand and worldwide who require high-quality tool steel solutions.

**High Speed Steel T42 bars** consist of about 1.25% carbon, 9% tungsten, 1.25% molybdenum, 3.8% vanadium, 4.0% cobalt, and 4.0% chromium. The incorporation of cobalt provides increased hot hardness, so the steel will be able to continue cutting efficiently at high temperatures. T42 provides exceptional wear resistance, high red hardness, and excellent edge retention. Mechanically, it has high compressive strength and toughness, allowing it to be used in complex, high-speed cutting operations. The steel is capable of high load-bearing and thermal stress capability, and hence it is a choice in demanding tool-making operations with a requirement of performance and reliability.

| Aisi No. | Work No. | C. | Si. | Mn. | Cr. | Mo. | V. | W. | Co. | |

| T-42 | 1.3207 | 1.28 | 0.23 | 0.20 | 4.15 | 3.55 | 3.25 | 9.5 | 10.0 |

| Density | 2.79 g/cm³ |

| Melting Point | 640 °C |

| Proof Stress | 270 MPa |

| Tensile Strength | 405 Min MPa |

| Elongation | 12 Min % |

| Bohler | AISI | BS | IS | JIS | DIN |

| S 700 | T42 | BT42 | XT125WCo10 CrMo4V3 | SKH-57 | (1.3207) |

| Thermal Expansion | 23.10 x10^-6 /K |

| Modulus of Elasticity | 73 GPa |

| Thermal Conductivity | 121-193 W/m.K |

Yes, T42 Alloy High-Speed Steel Bars can be heat treated. They are typically hardened through heat treatment processes like quenching and tempering to enhance hardness, wear resistance, and performance.

Welding T42 High-Speed Steel Bars is challenging due to their high carbon content and hardness. If welding is required, preheating and post-weld heat treatment are often necessary to prevent cracking and ensure strength.

T42 High-Speed Steel Bars should be stored in a dry, cool environment to prevent rust and corrosion. They should be kept off the ground, ideally on wooden or plastic pallets, and protected from moisture and extreme temperatures.

High Speed Steel T42 bars are widely applied to produce precision cutting tools like drills, end mills, reamers, taps, and form tools. The high red hardness and wear resistance of the alloy make it suitable for machining hardened steels, superalloys, and other hard materials. T42 is particularly preferred in aerospace, automotive, and die-making applications where tool performance and durability are paramount. Such bars are also employed in high-speed production where thermal fatigue and edge breakage are prevalent. Their hardness retention property under harsh cutting conditions makes T42 a top pick for challenging metal cutting and forming applications.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Anucha Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Bangkok, Thailand

Copyright 2024 Anucha Metals. All rights reserved