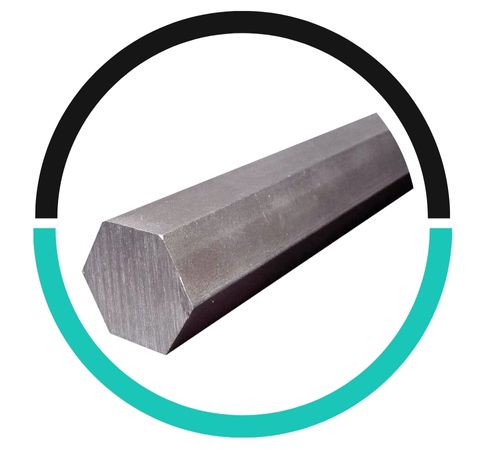

Anucha Metals is based in Bangkok, Thailand. We supply high-quality Alloy Steel Hex Bars made for precision engineering and strong applications. These bars have a six-sided hexagonal shape, which provides excellent machinability and tight size tolerances. They are perfect for CNC machining, making fasteners, and assembling mechanical parts. Our hex bars come in different alloy grades, including 4140, 4340, and EN19. Each bar meets ASTM, AISI, and EN standards and is tested for strength, hardness, and finish. Anucha Metals guarantees great surface quality, precise sizing, and reliable mechanical performance in every hex bar we provide.

Alloy steel hex bars usually contain carbon (0.3–0.6%), chromium, molybdenum, and nickel, depending on the grade. These elements help achieve high tensile strength (up to 1000 MPa), yield strength of up to 800 MPa, and excellent hardness. Heat-treated hex bars can be quenched and tempered for better wear and fatigue resistance. They offer tight size control, great machinability, and corrosion resistance in tough industrial conditions. The hex design makes it easy to grip during machining and gives increased torsional strength.

| Specifications | ASTM A182, ASME SA182 |

|---|---|

| Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Range | 5mm to 500mm Dia in 100mm to 6000mm Length |

| Diameter | 10 mm To 200 mm |

| Thickenss | 0.5mm to 500mm Diameter |

| High Speed Steel (HSS), HCHCR & OHNS in Grade | M2, M3, M35, M42, T-1, T-4, T-15, T-42, D2, D3, H11, H13, OHNS-01 & EN52 |

| Finish | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Length | 1000 mm Long To 6000 mm Long |

| Form | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

| Element | C | Cr | Mn | Mo | P | S | Si | Ni |

| F5 | 0.15 Max | 4.0-6.0 | 0.30-0.60 | 0.44-0.65 | 0.035 Max | 0.030 Max | 0.50 Max | 0.50 Max |

| F1 | 0.15 Max | 3.0-5.0 | 0.30-0.60 | 0.40-0.50 | 0.035 Max | 0.030 Max | 0.50 Max | 0.50 Max |

| F22 | 0.05-0.15 | 2.00-2.50 | 0.30-0.60 | 0.90-1.10 | 0.035 Max | 0.040 Max | 0.50 Max | – |

| F91 | 0.08-0.12 | 8.0-9.5 | 0.30-0.60 | 0.85-1.05 | 0.020 Max | 0.010 Max | 0.20-0.50 | 0.40 Max |

| F9 | 0.15 Max | 8.0-10.0 | 0.30-0.60 | 0.90- 1.10 | 0.030 Max | 0.030 Max | 0.50- 1.00 | – |

| F11 | 0.10-0.20 | 1.00-1.50 | 0.40-0.65 | 0.44-0.65 | 0.025 Max | 0.040 Max | 0.50-0.80 | – |

| Grade | Tensile Strength (ksi) min | Elongation (% in 50mm) min | Yield Strength 0.2% Proof (ksi) min |

| F9 | 415 | 30 | 205 |

| F5 | 275 | 485 | 20 |

| Size (mm) | Weight (kg/m) | Size (mm) | Weight (kg/m) | Size (mm) | Weight (kg/m) |

| 7 x 7 | 0.337 | 19 x 19 | 2.479 | 38 x 38 | 9.916 |

| 8 x 8 | 0.44 | 20 x 20 | 2.747 | 40 x 40 | 10.988 |

| 9 x 9 | 0.556 | 21 x 21 | 3.029 | 42 x 42 | 12.114 |

| 10 x 10 | 0.687 | 22 x 22 | 3.324 | 45 x 45 | 13.906 |

| 11 x 11 | 0.831 | 24 x 24 | 3.956 | 48 x 48 | 15.822 |

| 12 x 12 | 0.989 | 25 x 25 | 4.292 | 50 x 50 | 17.168 |

| 13 x 13 | 1.161 | 26 x 26 | 4.642 | 53 x 53 | 19.29 |

| 14 x 14 | 1.346 | 28 x 28 | 5.384 | 55 x 55 | 20.774 |

| 15 x 15 | 1.545 | 30 x 30 | 6.181 | 60 x 60 | 24.723 |

| 16 x 16 | 1.758 | 32 x 32 | 7.032 | 65 x 65 | 29.015 |

| 17 x 17 | 1.985 | 34 x 34 | 7.939 | 70 x 70 | 33.65 |

| 18 x 18 | 2.225 | 36 x 36 | 8.9 | 75 x 75 | 38.629 |

Alloy steel hex bars are manufactured by hot rolling or forging alloy steel billets, followed by precision machining, annealing, and surface finishing to achieve the desired size, strength, and quality.

The best finishes for corrosion resistance in alloy steel hex bars and rods include zinc plating, chrome plating, electropolishing, and black oxide coating, as well as applying epoxy or powder coatings for additional protection.

Alloy steel hex bars and rods are durable due to their high-strength alloy composition, including elements like chromium, molybdenum, and nickel, enhancing hardness, corrosion resistance, and resistance to wear and fatigue.

Alloy steel hex bars are commonly used to make fasteners, nuts, bolts, studs, and precise components. In automotive and mechanical engineering, they are used for gears, shafts, pins, and machine tool parts. Hex bars are preferred in CNC machining centers for creating tight-tolerance parts with less material waste. In oil and gas applications, they serve as valve stems and fittings. Their shape makes them ideal for wrenching components and other hex drive uses. Alloy steel hex bars combine strength, machinability, and precision, making them vital in modern industrial fabrication and component production.

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Anucha Metals is a leading manufacturer, supplier, and exporter of high-quality bars, rods, and forgings, catering to various industries in Bangkok, Thailand

Copyright 2024 Anucha Metals. All rights reserved